Diesel turbo losing power, whistling, or blowing smoke? Here’s what you need to know: modern diesel turbos—especially Variable Geometry Turbochargers in Powerstroke, Duramax, and Cummins engines—are complex systems combining precision mechanics with advanced electronics. At Branch Automotive in Littleton, CO, our ASE-certified team specializes in diesel turbo repair, using manufacturer-level diagnostics, a chassis dynamometer, and over a decade of diesel expertise to pinpoint and fix turbo issues before they cause catastrophic engine damage. From actuator replacement to full rebuilds, we back every job with a 24-month/24,000-mile warranty so you can tow, haul, and drive with confidence.

Now, let’s take a closer look at how modern turbo systems work, common failure signs, and why the right repair approach can save you thousands.

A Closer Look at the Rise of Modern Turbo Systems

Traditional turbochargers were essentially fixed devices. Exhaust gases spun a turbine wheel, which spun a compressor wheel, which forced more air into the engine. Simple, but not very smart. Variable Geometry Turbochargers revolutionized this concept by introducing moveable vanes inside the turbine housing that act like intelligent gatekeepers for exhaust flow.

These vanes can open and close in real-time, directing exhaust airflow over the inducer wheel with surgical precision. When your engine demands maximum power for towing, the vanes open wide to capture every bit of exhaust energy. When cruising at highway speeds, the vanes adjust to provide exactly the right amount of boost.

This precise control leads to much more accurate air volumes entering the engine, which means power delivery becomes incredibly smooth and consistent. It’s why today’s diesels feel so refined while simultaneously producing jaw-dropping amounts of horsepower and torque.

Understanding the Real Challenges in Today’s Diesel Turbo Repairs

Most people think a turbocharger is just a spinning device that either works or doesn’t. This misconception leads to expensive mistakes and repeated failures. Modern diesel turbochargers are complex electro-mechanical systems with multiple sensors, actuators, and control modules working in perfect harmony.

The Electronic Brain Behind the Boost

Your truck’s Engine Control Module (ECM) constantly monitors dozens of parameters to control turbocharger operation:

- Exhaust gas temperature sensors prevent overheating damage

- Boost pressure sensors ensure optimal air delivery

- Variable vane position sensors confirm proper geometry adjustment

- Mass airflow sensors validate actual versus commanded airflow

- Barometric pressure sensors compensate for altitude changes

When any of these sensors provides incorrect information, your turbocharger system can’t function properly. This is why accurate diagnosis requires manufacturer-specific scan tools and a deep understanding of how these systems interact.

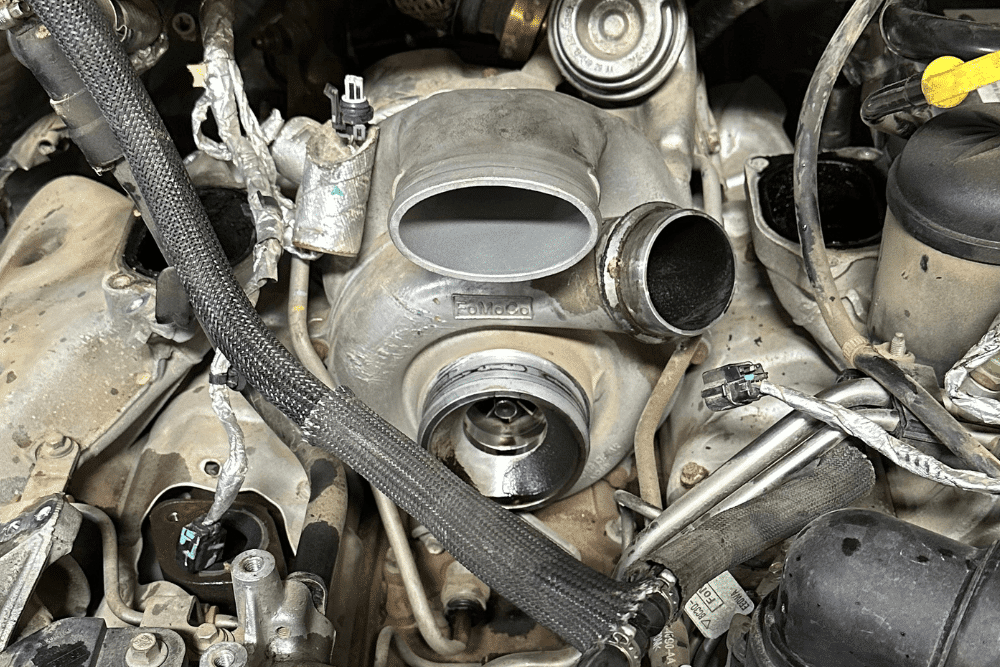

The Mechanical Marvel: Inside Variable Geometry Systems

Inside the turbine housing, a ring of aerodynamically shaped vanes surrounds the turbine wheel. Each vane can rotate on its axis, controlled by a sophisticated actuator system that responds to electronic commands instantly.

The tolerances involved are incredibly tight, with components spinning at speeds exceeding 100,000 RPM while operating in exhaust gas temperatures reaching 1,800 degrees Fahrenheit. This precision is why turbocharger repair demands specialized expertise.

Engine-Specific Turbocharger Challenges: Know Your Diesel

Ford Powerstroke: The Precision Performer

Ford’s 6.7L Powerstroke engines use a single Variable Geometry Turbocharger, known for responsive performance but sensitive to maintenance neglect. Common issues include VGT vane problems from carbon buildup, actuator failures, and oil system-related issues like feed line restrictions and seal deterioration.

Chevrolet/GMC Duramax: The Workhorse Wonder

Duramax engines feature sophisticated systems requiring expert-level diagnosis. Unique challenges include variable vane position sensor failures, boost pressure control issues, and complex exhaust aftertreatment system interactions.

Dodge RAM Cummins: The Torque Monster

Cummins engines are legendary for durability, but their turbocharger systems still require knowledgeable attention. Common concerns involve wastegate actuator calibration issues, variable geometry mechanism wear, and exhaust gas recirculation system integration problems.

Don’t risk engine damage. Schedule your turbo diagnosis today!

The Real Cost of Turbocharger Neglect

When a turbocharger fails catastrophically, metal debris can be ingested into the engine’s intake system, potentially damaging intercooler cores, intake manifold components, engine valves, and, in severe cases, pistons and cylinder walls. The cost difference between addressing turbocharger issues early versus dealing with secondary damage can easily be tens of thousands of dollars.

Diagnostic Excellence: How Real Experts Approach Turbo Problems

Professional turbocharger diagnosis requires sophisticated equipment and methodical approaches. Chassis dynamometer testing allows technicians to observe turbocharger behavior under controlled conditions that replicate actual driving scenarios. Manufacturer scan tool analysis provides access to detailed turbocharger control parameters that generic code readers can’t reach. Comprehensive boost leak testing identifies even small air leaks that can dramatically affect turbocharger efficiency.

What Makes Branch Automotive the Top Choice for Turbo Repair

After understanding the complexity involved in modern turbocharger systems, choosing the right repair facility becomes crucial. At Branch Automotive, we’ve dedicated over a decade to becoming true diesel specialists.

Unmatched Technical Credentials

Our owner, Parker Branch, holds GM World Class Master certification, representing the highest level of certification in General Motors’ Service Technical College program. Branch is also an ASE World Class Tech, while our team includes multiple ASE Master Technicians, a Ford factory-trained diesel specialist, and takes part in continuous education on evolving turbocharger technology.

State-of-the-Art Equipment

Our facility houses a chassis dynamometer that can simulate mountain grades, highway speeds, and heavy towing conditions, allowing us to diagnose problems other shops can’t reproduce. We maintain current manufacturer scan tools and software for Ford/Powerstroke, GM/Duramax, and Dodge/Cummins applications.

Our Commitment to Excellence

Our shop philosophy centers on three core principles that drive everything we do:

Better Value through better communication, better practices, better people, better availability, and better turnaround times by being specialized. We refuse to cut corners or use inferior parts – every turbocharger repair receives meticulous attention whether it’s a simple actuator replacement or a complete rebuild.

Better Industry means refusing to be mediocre, with absolute dedication to doing the repair as it should be done. We take pride in our work all through the shop, which is why our digital inspection process ensures complete transparency with detailed photographs and explanations.

Better Life for our customers and staff. We hire the best people, use the best tools, and install the best parts to keep you where you belong: in your vehicle. That’s why we back our turbocharger work with a comprehensive 24-month/24,000-mile nationwide warranty, giving you peace of mind wherever your diesel takes you.

Smart Steps to Extend the Life of Your Diesel Turbocharger

Proper maintenance is your turbocharger’s best friend. Following these guidelines can dramatically extend turbo life and prevent costly failures.

Oil Change Intervals: The Foundation of Turbo Health

Clean oil is critical for turbocharger longevity. We recommend 5,000-mile oil change intervals using high-quality oil that meets manufacturer specifications. Given that turbocharger shaft speeds can exceed 100,000 RPM, even slightly contaminated oil can cause bearing damage.

Essential Maintenance Practices

A clean air filter ensures unrestricted airflow and prevents compressor wheel damage. Clean diesel fuel and properly maintained fuel filters prevent combustion irregularities that stress turbocharger components. Allow your engine to warm up before heavy acceleration, and let it idle briefly after hard driving to prevent thermal shock damage.

Warning Signs: When to Seek Professional Help

Recognizing early warning signs can save you from major turbocharger failure and secondary engine damage. Don’t ignore these symptoms:

Performance Related:

- Reduced power or sluggish acceleration

- Excessive exhaust smoke (black, blue, or white)

- Poor fuel economy

- The engine is struggling under load

Audible Indicators:

- Unusual whistling or grinding noises

- Changes in engine sound quality

- Rattling from the turbocharger area

Electronic Warnings:

- Check engine lights

- Reduced power mode activation

- Boost pressure fault codes

Early intervention by qualified diesel turbo mechanics in Littleton can often prevent minor issues from becoming major problems.

Frequently Asked Questions About Diesel Turbocharger Repair

How long does a turbocharger typically last on a diesel truck?

With proper maintenance, a diesel turbocharger can last 150,000 to 200,000 miles. However, factors like driving habits, maintenance intervals, and operating conditions significantly impact lifespan. Trucks used for heavy towing or operated in dusty environments may require turbo service sooner.

Can I drive my diesel truck with a failing turbocharger?

While you may be able to drive short distances, continuing to operate with a failing turbo risks catastrophic engine damage. Metal debris from turbo failure can destroy pistons, valves, and cylinder walls, turning a turbo repair into a complete engine rebuild.

What's the difference between turbo rebuild and replacement?

A rebuild involves disassembling the turbocharger, replacing worn components, and reassembling to factory specifications. Replacement involves installing a new or remanufactured unit. The choice depends on the extent of damage and cost-effectiveness for your specific situation.

Why do some shops quote much lower prices for turbo work?

Lower quotes often indicate the use of inferior aftermarket parts, incomplete diagnosis, or a lack of proper testing equipment. Quality turbo repair requires OEM or OEM-equivalent parts, proper diagnosis, and validation testing to ensure lasting repairs.

How can I tell if my turbo problem is related to the exhaust aftertreatment system?

Modern diesels integrate turbocharger operation with DPF, SCR, and EGR systems. Symptoms like excessive regeneration cycles, unusual exhaust smoke colors, or fault codes related to emissions systems often indicate interconnected problems requiring comprehensive diagnosis.

Trust Your Turbo to Colorado's Diesel Experts

Your diesel truck’s turbocharger represents sophisticated engineering that demands specialized attention, not generic repair approaches. From our Littleton facility, we serve discerning truck owners throughout Highlands Ranch, the Denver metro, and the entire Colorado Front Range who refuse to compromise on quality.

Before your turbo problem becomes an engine rebuild, contact the diesel turbo specialists at Branch Automotive at (303) 771-2224, visit us at 6030 East County Line Road in Littleton, Colorado 80126, or request your consultation online and discover why your turbocharger deserves nothing less than expert care.